- Acknowledgements

- Introduction

- Chapter 1: Measurement Tools, Layout & Job Planning

- Chapter 2: Basic Hand Tools

- Chapter 3: Filing & Sawing

- Chapter 4: Grinding, Reaming, Broaching & Lapping

- Chapter 5: Drills & Drilling Operations

- Chapter 6: Threads & Threading

- Chapter 7: Turning Operations

- Chapter 8: Milling Operations

- Chapter 9: Fastening Methods

- Chapter 10: Why Steel Hardens

- Chapter 11: Safety & Good Shop Practices

- Chapter 12: Other Shop Know-how

- Appendix I: Sharpening Steel Lathe Tools

- Appendix II: Surface Speed Table & Cutting Tool Selector Chart

- Appendix III: Decimal Equivalents of Fractional, Letter & Metric Drills

- Glossary

- Index

Chapter 2

Basic Hand Tools

The chief cause of problems is solutions.

—Richard Sennett

Introduction

Having just the right tool for the job makes all the difference in getting the job done quickly and correctly. No place is this more important than in the machine shop. This chapter looks at fourteen different categories of basic machine shop hand tools and how they are used. For every category of tool there are dozens of variations in size, shape, and design, so it is easy to see why most machinists have hundreds of tools in their rollaway chests. There are another dozen types of hand tools, such as reamers, taps, and dies, which are equally important, and will be covered in later chapters. Although socket, open-end, and box-end wrenches are basics and often used in the machine shop, their use is familiar to most and will not be covered here.

We will also examine two hand-held power tools, the reciprocating saw and the portable band saw. They are important for cutting metal stock into smaller sizes prior to machining.

From quality tools to budget imports there is a bigger selection of tools available today than ever before. Actually seeing and handling the quality and budget alternatives before making a choice between them is always a good idea. Sometimes there is a big difference between them and sometimes not, so be aware of this before making a purchase. Many budget tools look good, but that is the only good thing about them. Paying list price for a quality tool is often the better value. Industrial tool catalogs, aside from being fun wish books, are a good way to learn about the myriad of tools now available which may someday help you solve a problem.

Bench Vise & Jaw Covers

What are the uses of a bench vise?

Bench vises:

- Hold work securely when filing, sawing, or drilling.

- Support work across its open jaws when driving out a pin with a drive punch.

- Bend small metal bars, rounds, and sheet goods by inserting them up to the bend point and striking the work with a ball peen hammer.

- Assemble force-fit parts by squeezing them together.

- Hold bench blocks and miniature anvils at a convenient level.

- Position work for soldering or brazing.

- Provide a small anvil behind the back jaw for light hammering.

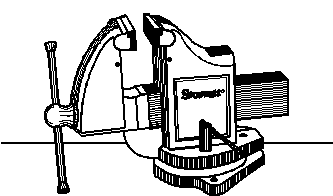

See Figure 2–1.

Figure 2–1. Machinists’ bench vise

Why use protective vise jaws and how are they made?

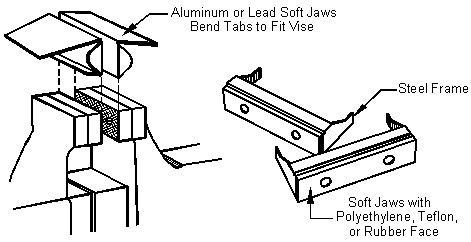

They prevent damage to the workpiece from the hardened and diamond- serrated vise jaws. There are many different materials used to make them. Rubber, lead, Teflon® and polyethylene make very soft vise jaws, aluminum and brass, slightly harder ones. Fiberboard, Masonite® and wood blocks also work well. Some protective jaws lay over the vise jaws, Figure 2–2, some have tabs bent to clasp the vise, Figure 2–3, and others are held against the steel vise jaws with magnets.

Figure 2–2. Protective vise jaws: brass angles that sit on vise jaws

(left) and molded rubber jaws for holding gun barrels (right).

Figure 2–3. Protective vise jaws held in place by metal tabs.

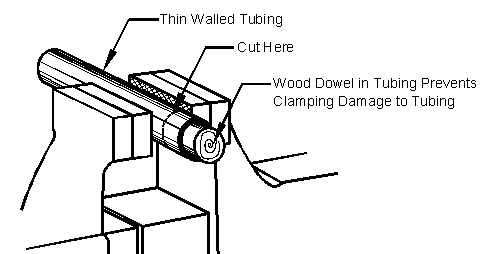

Sometimes the workpiece must be protected from the inside. To do this, place a wooden dowel inside the thin-walled tubing to prevent the vise from crushing the tubing, Figure 2–4. The dowel must fit snugly inside the tubing.

Figure 2–4. Using a dowel to safely clamp thin-walled tubing.

To hold a specific part, sometimes the best approach is to replace the original vise jaws with shop-made ones with cylindrical or V-shaped grooves, Figure 2–5. Two screws hold each jaw in place, making it easy to install new ones. Often custom jaws do not need to be hardened and serrated, so they can be made of brass or aluminum for easy fabrication. Besides gripping a part firmly without marking it, custom jaws will not come loose from the vise as other designs will.