Why Traditional Machine Tools Remain Important

The economics of NC machines has driven manually-controlled lathes and mills from the production floor, but these traditional machines still play a critical role in many applications. When prototypes or just a few parts are needed, a traditional machinist will be done long before a programmer has entered his last line of code. This makes manual machines more cost effective. Here are some more examples:

- Machinery Repair

As old-line machinery companies disappear, their machines outlive them, but not their parts departments. Finding parts for an old, but still hard-working, Linotype machine, Maserati or Cessna can be nearly impossible, but can be economically repaired with custom machine parts. When parts availability and speed of repair are critical, nothing competes with manually-controlled lathes and mills. - Jigs and Fixtures

Modifications of existing tooling can be made quickly and easily and changes can be made incrementally to “sneak up” on the best design. - Product Designs

Industrial model makers and inventors produce their initial designs with traditional machine tools, which allows them the flexibility to modify them many times until perfect. - Gunsmithing

Because each job is unique to each firearm, writing NC programs is a waste of time and money. - Instrument Fabrication

Precision instruments for medicine and scientific research are often one-of-a-kind, made to order devices that, unless you are rolling in money, are best produced on manually-controlled machine tools. The quality can be the same and the delivery time shortened using manual tools.

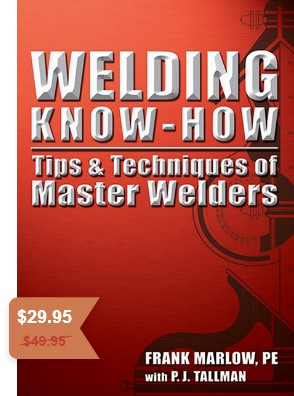

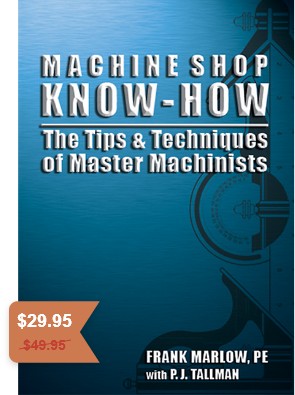

Why Our Books are Special

Our books are easy to understand because they are written for craftsmen, not academics. There are no confusing theoretical discussions, just good, solid information that even beginners can grasp. Our books can be read cover to cover or in short bites, whatever your schedule allows. Here are a few features:

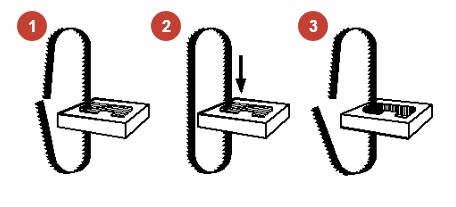

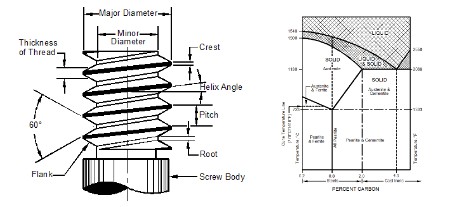

Each book has 500 to 600 custom line drawings—one on nearly every page—not blurry, old stock photos from machinery manufacturers and Army manuals. These detailed drawings make even complex concepts understandable.

To save you time and trouble, our books have step-by-step procedures for operating machine tools based on the knowledge, short cuts and techniques of more than a dozen toolmakers, moldmakers, welders and fabricators. They learned from their mistakes so you don’t have to.

Dozens of detailed instructions for useful jigs, fixtures and shop-made tools designed to improve your skills and make your shop projects come out right.

Our books teach you how to fix what’s broken without calling a repairman.